Portable Dust Extraction Systems Exporters – Activated carbon adsorption, desorption, catalytic combustion – Jinming

Portable Dust Extraction Systems Exporters – Activated carbon adsorption, desorption, catalytic combustion – Jinming Detail:

Introduction

Workshop is engaged in the production operation will poduce the harmful gas such as stimulation of pollutants, to nature ecology and plant environmental hazards can cause air pollution, waste gas emissions from the equipment will be collected, the use of activated carbon adsorption tower will be treated as waste gas to the air pollutant emission standards before discharge into the atmosphere, so as not to ause the harm of environment and staff.

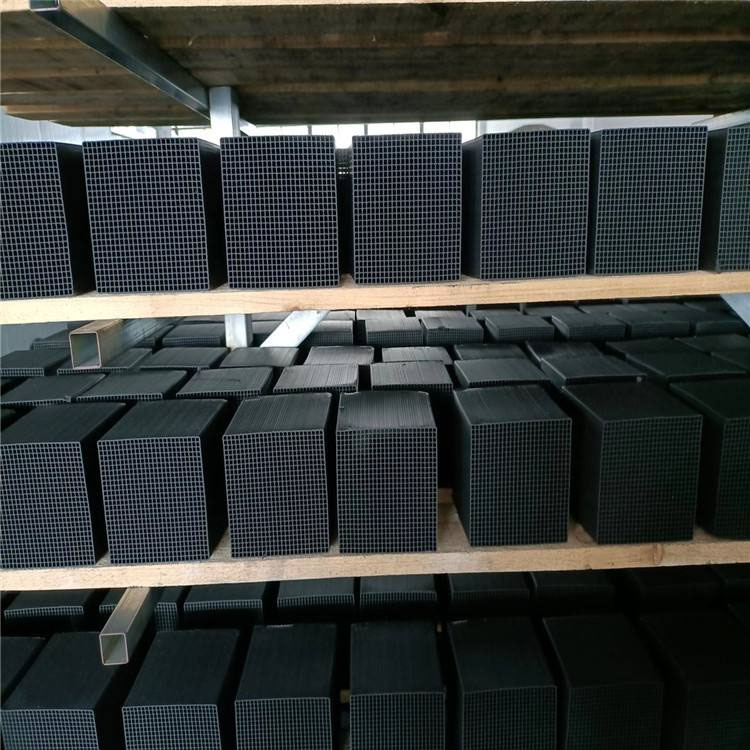

Activated carbon absorption, stripping, catalytic combustion is one of my company a new generation of VOCs processing equipment, is the element of adsorptive enrichment and thermal oxidation unit a organically, mainly is suitable for the low concentration organic gases and should not be used directly or catalytic combustion method and adsorption method of recycling treatment of organic waste gas, especially for large volume processing, Satisfactory economic and social effects can be obtained. After adsorption, purification and desistation, it is converted into organic waste gas with small air volume and high concentration, which is treated by thermal oxidation, and the heat released by the combustion of organic matter is utilized.

Technical characteristics of activated carbon adsorption and desorption catalytic combustion device

1. Adsorption purification, stable treatment effect, to ensure that the exhaust gas discharge standards.

2. With manual and automatic desorption function, the choice of precious metal catalyst, through catalytic combustion reaction will be organic matter conversion, catalytic.

3. Adopt PLC control, supporting can operate touch screen, easy to operate, simple maintenance and management.

4. With multiple measures, the main reactor is equipped with explosion relief device, set up multi-point temperature detection, with fault alarm and emergency treatment ability.

Suitable for all kinds of industrial waste gas treatment

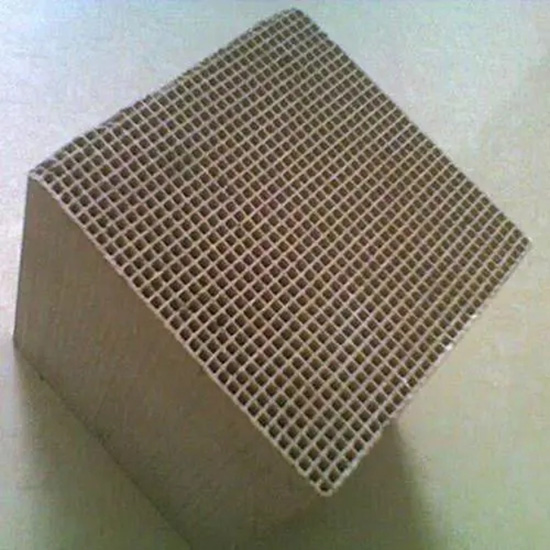

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers' needs for Portable Dust Extraction Systems Exporters – Activated carbon adsorption, desorption, catalytic combustion – Jinming , The product will supply to all over the world, such as: Lithuania, Paraguay, Durban, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.