The process plane setting is the key item in the process design of coating workshop. It should be the coating process, all kinds of coating equipment (including conveying equipment) and auxiliary devices, logistics flow, coating materials, five aerodynamic power supply and other optimization combination, and in the layout plan and section plan, it is involved in a wide range of professional knowledge, high technical content of the design work. The plane layout design is a very important part in the whole painting workshop design, it is based on the needs of the process, the mechanization equipment, thermal non-standard equipment and auxiliary equipment and other reasonable combination, arranged in the painting workshop. It is the main part of the process design document, is the synthesis of all the calculation results, it needs to the production of equipment and equipment with the number and characteristics, the number of staff, the organization of special operations and the workshop and the adjacent workshop between the transport relationship and other aspects to give a clear description. In short, it can vividly reflect the whole picture of the painting workshop, is also an important basis for the preparation of process instructions, mechanical equipment design, thermal non-standard equipment and civil engineering public professional design. This is a complex task, which should be repeated several times before it can be completed. The layout of the floor plan is mainly based on workshop tasks, design principles, basic data and calculation data of mechanized equipment and non-standard equipment. Generally, the following principles should be observed:

1, according to the workshop scale, choose the size of the plan, the general proportion is 1:100, with zero or zero extension drawing.

2, in the case of the transformation of the old factory building, first of all, according to the original data of the factory building, draw a good plant plan, such as the new factory building is in accordance with the design requirements of the general layout, combined with the process needs to determine the length, width and height of the factory building.

3, according to the process flow chart, mechanized transportation flow chart and the relevant equipment size calculation data, from the workpiece entrance end of the equipment layout design.

4. Attention should be paid to not making the main body of the equipment too close to the plant column wall, and the installation space of the public power pipeline, ventilation pipeline and the installation and maintenance space of painting equipment should be reserved. When the old factory building is reformed, or the necessary clearance cannot be guaranteed due to some special circumstances, the public power pipeline should be avoided as far as possible.

5. The required area of auxiliary equipment (such as driving and tensioning device of transport chain, auxiliary equipment of pre-treatment, electrophoresis and spraying equipment, etc.) should be fully considered. In principle, the auxiliary equipment should be as close as possible to the main equipment, in which the material and waste discharge equipment should consider sufficient operating area, and there should be transport channels.

6, open manual operation station, in addition to ensure sufficient operating area, but also consider the station, station equipment, material box, material rack location and the corresponding material supply and transportation channel.

7, from the workshop as a whole to fully consider the logistics channel, equipment maintenance equipment, safety fire and safety evacuation door, if it is a multi-storey plant, to consider the layout of safety evacuation stairs.

8, according to the process of different functions and different requirements for the work environment or clean degree of different requirement, can press the whole coating workshop primer, seal line, coating and paint spraying, drying, manual operation, auxiliary equipment such as partition layout, is advantageous for the equipment, production line and workshop cleanliness control, also facilitate heat recycling, etc.

9, for the public professional equipment and some auxiliary devices of the area should be reserved (such as plant heating and air conditioning machine, central control room, laboratory, workshop office, all kinds of materials and spare parts warehouse, equipment and tools maintenance room, toilet, power distribution room, power entrance, etc.).

10. In the layout of the transitional scheme combining distance and distance, the layout plan should fully consider the easy expansion and transformation in the future. In principle, the expansion part can be separated from the existing part, so that normal production can not be affected by the expansion, and the transition should be realized in a very short time.

11, in the old factory renovation, the use of old plant, equipment layout to fully consider the structural characteristics of the original plant, as far as possible not to change the original plant, must change, to consider the possibility of change.

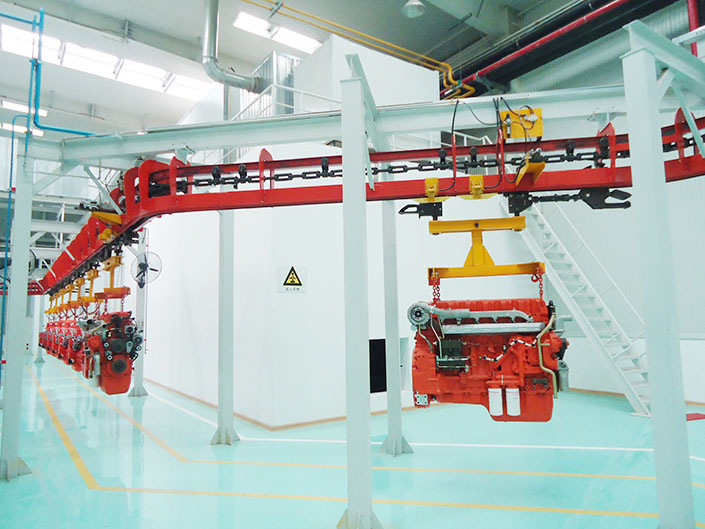

12. The outline size and positioning size of the equipment in the plan should be clear. The general positioning datum is the axis or the center line of the column, and sometimes it can be based on the wall (not recommended). Mechanized transport equipment to indicate the direction of operation, catenary to indicate the elevation of track top.

13. Standard symbols must be used because the plan reflects a lot of content, and each regional design department has its own legend. Each plan must have a legend, which can be explained in the description column on the plan.

14, the layout plan should include the plan, elevation and section, if necessary to draw the position of the painting workshop in the general drawing. If one drawing cannot fully reflect the layout, two or three drawings can be used. The principle is to make it easy for the reader to understand the overall picture of the workshop. The part that is not clear in the drawing can be explained in the illustration bar on the drawing.

In the layout of stations and equipment, the working area, pedestrian passage and transportation passage can be designed according to the following dimensions.

The main body of equipment is 1~1.5 meters away from the plant column or wall; The width of the working area is 1~2 meters; The width of the pedestrian passage for maintenance and inspection of equipment is 0.8~1 m; The width of the pedestrian passage is 1.5 meters; The width of the transport channel that can push the trolley is 2.5 meters; Manual handling distance should not be greater than 2.5 meters; The distance from the station to the near safety exit or stairway should not be more than 75 meters, in a multi-storey building should not be more than 50 meters.

Post time: Mar-16-2022