High Quality Vacuum Dust Collector – Filter cartridge bag dust collector – Jinming

High Quality Vacuum Dust Collector – Filter cartridge bag dust collector – Jinming Detail:

Introduction

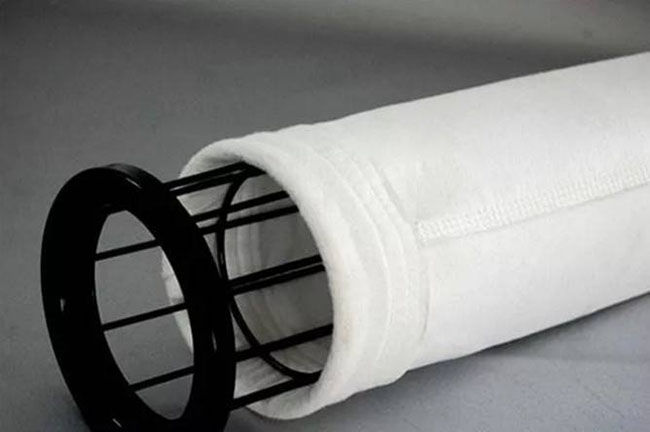

PL series single machine dust removal equipment is the domestic more dust removal equipment, the equipment by fan, filter type filter, dust collector trinity. The filter barrel of the PL single-machine bag filter is made of imported polyester fiber, which has many advantages such as high dust removal efficiency, fine dust collection, small size, convenient installation and maintenance, long service life and so on. PL series single machine dust collector in the equipment operation process, due to the continuous precipitation of dust on the surface of the filter barrel in the small PL single machine dust collector, gradually formed resistance, will soon reach saturation on the surface of the filter barrel, when a certain saturation resistance value, automatic pulse back blowing system, automatic cleaning. PL series single – machine dust collector is realized by spraying compressed air. The filter cylinder in turn single cleaning, so in the cleaning process to ensure the flow of air, so the PL single bag filter can work for 24 hours, dust removal effect is still good.

Bag dust collector is a kind of standard general bag dust collector, the research and development of the main equipment is on the basis of absorbing the German equipment process and work experience, and closely combined with the specific application situation in Mainland China and developed; KDS explosion-proof bag dust collector adopts full negative pressure work, filter carrier for dust bag, its material mainly uses anti-static filter material or flame retardant material, supporting dragon skeleton and Wenfeng tube, so that it is more stable, dust removal effect is more stable; The equipment body adopts explosion-proof structure design, withstanding pressure up to -10000Pa; The equipment body is installed with explosion-discharging safety device to protect the equipment body will not be damaged because of explosion; Electrical equipment parts are explosion-proof standards, including: solenoid valve, pulse controller, fan motor, electrical control cabinet, etc.

Application field

Explosion-proof bag dust collector is also suitable for “industry and trade industry key combustible dust catalogue” involved in all dust industries; Industries include: metal products processing, agricultural and sideline products processing, wood / paper products processing, textile processing, rubber and plastic products processing, metallurgy, non-ferrous metals, building materials, machinery processing, light industry, tobacco, etc.

Product advantage

1. High dust removal efficiency, using PTFE coated filter material, filtering efficiency can reach more than 99%, dust concentration of dust precipitator outlet gas in 10mg/m3, the sub-micron particle size of fine dust has a higher classification efficiency.

2. The wide range of air volume, small only 1min number of m3, up to 1min tens of thousands of m3, can be used for high temperature dust removal of industrial furnaces, which is the high temperature requirements of filter barrel dust collector can not reach.

3. Simple structure, convenient maintenance and operation, full automatic operation, reduce a lot of labor costs.

4. Under the premise of ensuring the same high dust removal efficiency, the cost is lower than the electrostatic precipitator.

5. Use glass fiber, polytetrafluoroethylene, P84 and other high temperature resistant filter material, can run in high temperature conditions of more than 200℃, which is the temperature requirements of the explosion-proof filter cartridge dust collector can not reach.

6. Explosion-proof bag dust collector due to increase a variety of explosion-proof measures, to protect the workshop and personal and property safety, purification workshop at the same time, to bring you the security of wealth.

Suitable for all kinds of industrial dust control

Product detail pictures:

Related Product Guide:

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme for High Quality Vacuum Dust Collector – Filter cartridge bag dust collector – Jinming , The product will supply to all over the world, such as: New Zealand, British, Austria, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!