High Quality Paint Drying Room Factory – Drying professional 4-element professional hot blast stove S-2000 – Jinming

High Quality Paint Drying Room Factory – Drying professional 4-element professional hot blast stove S-2000 – Jinming Detail:

Introduction

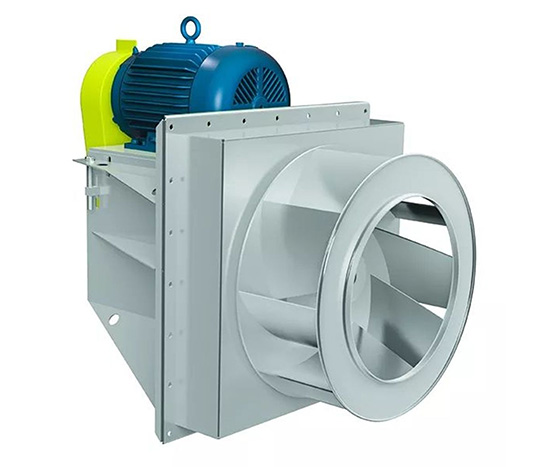

SYL. Series fan embedded ternary indirect heat exchange unit is built in Yancheng Jinming Coating Co., LTD. Based on the series of modular renewal of circulating air heat exchange products, set fan, filter, combustion, (electricity, heat conduction oil, steam, etc.) and heat exchange device as a whole, collectively referred to as the ternary hot blast stove.

It receives the ESH. Series of high efficiency, energy saving, safety and other advantages, so that the hot air source quality is higher, the overall structure is more in line with the trend of modernization.

This product was officially put into market and mass production at the end of 2014. Several years of operation and practice have made SYL. The series heat exchanger units have been approved by the majority of users and recommended by the major domestic design institutes, and become the new leading products with international standards in the field of hot air drying and heating, especially in the coating drying lines of automobiles, locomotives, motorcycles and agricultural vehicles.

Scope of Application

1. Widely used in automobile, motorcycle, locomotive, plastic parts, bumper and other coating production lines.

2. Widely used in refrigerator, air conditioner, chassis and other home appliances coating production line.

3. Used for hot air drying of grain, seafood, wood, self-adhesive and so on.

Technical Features

1. Good overall performance

2. High heat exchange efficiency

3. Fast temperature rise

4. Low energy consumption

5. Complete models

6. Good safety performance

7. Easy to operate

Used for all kinds of workpiece painting, other models can be customized.

Product detail pictures:

Related Product Guide:

Having a sound small business credit score, outstanding after-sales services and modern manufacturing facilities, we've got earned an fantastic reputation among our buyers across the globe for High Quality Paint Drying Room Factory – Drying professional 4-element professional hot blast stove S-2000 – Jinming , The product will supply to all over the world, such as: Somalia, Cape Town, Cambodia, Our solutions have national accreditation requirements for qualified, good quality products, affordable value, was welcomed by individuals all over the world. Our products will continue to improve inside the order and appear forward to cooperation with you, Definitely should any of those goods be of curiosity to you, be sure to letus know. We'll be satisfied to supply you a quotation up on receipt of the detailed needs.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!