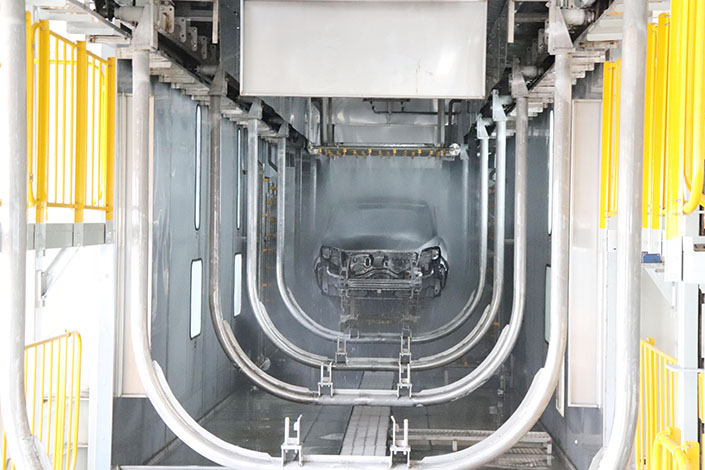

High Quality Electrophoretic Coating Machine Suppliers – Spray type pretreatment production line – Jinming

High Quality Electrophoretic Coating Machine Suppliers – Spray type pretreatment production line – Jinming Detail:

Coating pretreatment includes degreasing (degreasing), rust removal, phosphating three parts. Phosphating is the central link, degreasing and rust removal is the preparation process before phosphating, so in production practice, we should not only take phosphating work as the focus, but also start from the requirements of phosphating quality, do a good job in addition to oil and rust removal, especially pay attention to the mutual influence between them.

Degreasing derusting

With the development of industry, environmental protection and the improvement of working conditions have become the common concern of people. Therefore, the need of environmental protection should be taken into account when selecting agents. Therefore, the choice of oil removal agent requires simple preparation, deconfouling ability is strong, does not contain sodium hydroxide, silicate, OP emulsifier and other components that are difficult to clean at room temperature, easy to wash at room temperature, does not contain toxic substances, do not produce harmful gases, good working conditions. The selection of rust remover requires the inclusion of promoters, corrosion inhibitors and inhibitors, can improve the speed of rust removal, prevent the workpiece from over-corrosion and hydrogen embrittlement, can better inhibit acid fog. Is especially worthy of acid mist inhibiting, occurring in the process of pickling acid mist, corrosion of equipment and plant, not only pollute the environment, and can cause tooth decay, dental conjunctival redness, tears, pain, dry throat, cough and other symptoms, so effectively inhibit acid mist, not only the need of environmental protection, or for the sake of health to the worker’s needs.

Water washing

Washing after oil removal and rust removal, although it belongs to the auxiliary process before painting, it also needs to cause enough attention. After oil removal and rust removal, the surface of the workpiece is easy to adhere to some non-ionic surfactants and CL-. If these residual substances are not cleaned thoroughly, they may cause phosphating film thinning, linear defects, and even phosphating. Therefore, to improve the quality of water washing after oil removal and rust removal, it is necessary to go through multiple rinses, two rinses, time 1-2min, and frequently replace water to ensure that the PH value of water is between 5-7.

Phosphating

The so-called phosphating, refers to the metal workpiece after containing dihydrogen phosphate acid solution treatment, chemical reaction and in its surface to generate a layer of stable insoluble phosphate film, the film is called phosphating film. The main purpose of phosphating film is to increase the adhesion of coating and improve the corrosion resistance of coating. There are many methods of phosphating, according to the temperature of phosphating, can be divided into high temperature phosphating (90-98℃), medium temperature phosphating (60-75℃), low temperature phosphating (35-55℃) and normal temperature phosphating.

Passivation

The passivation technology of phosphating film is widely used in North America and European countries. The passivation technology is based on the characteristics of phosphating film itself. The phosphating film is thin, generally in 1-4G /m2, the maximum is not more than 10g/m2, the free pore area is large, and the corrosion resistance of the film itself is limited. Some even in the drying process on the rapid yellow rust, after phosphating a passivation closed treatment, can be phosphating film pore exposed metal oxidation, or the formation of passivation layer, phosphating film can play a filling, oxidation, make phosphating film stable in the atmosphere.

Drying of phosphating film

Drying the phosphating film can play two roles, on the one hand, it is to prepare for the next process to remove the water on the surface of the phosphating film, on the other hand, it is to further improve the corrosion resistance of the film after coating.

To establish a coating pretreatment line, the process design must be completed before the design, manufacture and installation of non-standard equipment. Therefore, the process design is the foundation of the production line, and the correct and reasonable route will have a good impact on the production operation and product quality.

Used for all kinds of workpiece painting, other models can be customized.

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for High Quality Electrophoretic Coating Machine Suppliers – Spray type pretreatment production line – Jinming , The product will supply to all over the world, such as: Johor, Afghanistan, Senegal, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

We have been looking for a professional and responsible supplier, and now we find it.