Grinder With Dust Extraction Suppliers – Activated carbon adsorption, desorption, catalytic combustion – Jinming

Grinder With Dust Extraction Suppliers – Activated carbon adsorption, desorption, catalytic combustion – Jinming Detail:

Introduction

Workshop is engaged in the production operation will poduce the harmful gas such as stimulation of pollutants, to nature ecology and plant environmental hazards can cause air pollution, waste gas emissions from the equipment will be collected, the use of activated carbon adsorption tower will be treated as waste gas to the air pollutant emission standards before discharge into the atmosphere, so as not to ause the harm of environment and staff.

Activated carbon absorption, stripping, catalytic combustion is one of my company a new generation of VOCs processing equipment, is the element of adsorptive enrichment and thermal oxidation unit a organically, mainly is suitable for the low concentration organic gases and should not be used directly or catalytic combustion method and adsorption method of recycling treatment of organic waste gas, especially for large volume processing, Satisfactory economic and social effects can be obtained. After adsorption, purification and desistation, it is converted into organic waste gas with small air volume and high concentration, which is treated by thermal oxidation, and the heat released by the combustion of organic matter is utilized.

Technical characteristics of activated carbon adsorption and desorption catalytic combustion device

1. Adsorption purification, stable treatment effect, to ensure that the exhaust gas discharge standards.

2. With manual and automatic desorption function, the choice of precious metal catalyst, through catalytic combustion reaction will be organic matter conversion, catalytic.

3. Adopt PLC control, supporting can operate touch screen, easy to operate, simple maintenance and management.

4. With multiple measures, the main reactor is equipped with explosion relief device, set up multi-point temperature detection, with fault alarm and emergency treatment ability.

Suitable for all kinds of industrial waste gas treatment

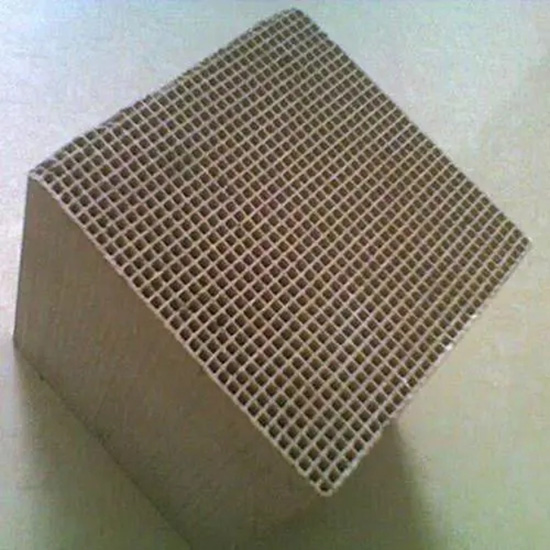

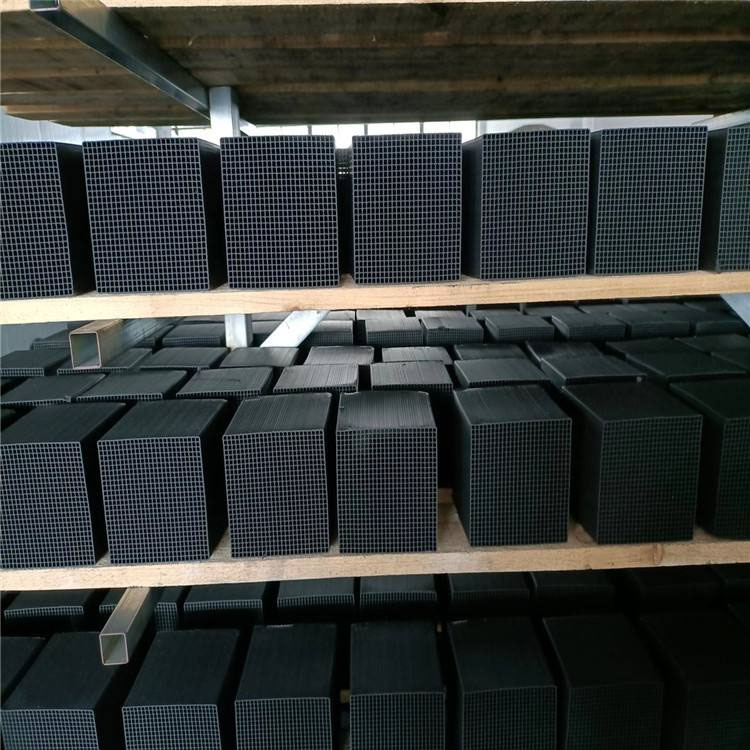

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Grinder With Dust Extraction Suppliers – Activated carbon adsorption, desorption, catalytic combustion – Jinming , The product will supply to all over the world, such as: Juventus, Costa Rica, Guinea, All these products are manufactured in our factory located in China. So we can guarantee our quality seriously and availably. Within these four years we sell not only our products but also our service to clients throughout the world.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!