China Precipitator Exporters – RTO regenerative waste gas incinerator – Jinming

China Precipitator Exporters – RTO regenerative waste gas incinerator – Jinming Detail:

Introduction

RT0 is also known as regenerative heating garbage incinerator, is a kind of environmental protection machinery that depends on heat energy to immediately ignite the waste gas, which can solve the waste gas in spraying, painting, packaging and printing, plastics, chemical plants, electrophoresis principle, spraying, electronic devices and other basically all fields. For the waste gas with the concentration value in the range of 100-3500mg /m3, RTO has the practical effect that other cleaning technologies cannot achieve, in addition to the higher concentration of organic chemical waste can also be concentrated according to the absorption into the RTO direct combustion equipment!

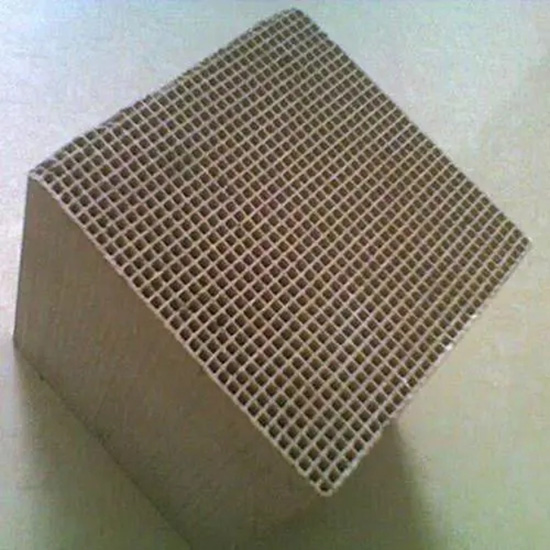

RTO regenerative heating garbage incinerator is composed of engine combustion chamber, ceramic packed bed and transfer valve. Porcelain fill bed can make the thermal energy acquisition of a great degree, after the heat detection of the utilization rate of 95%, so in the application of RTO to solve the industrial production of organic waste gas (VOCs), the requirements can save a lot of fuel consumption, reduce the cost of cleaning waste gas, easily over the environmental assessment.

RTO heats organic waste gas to above 760°C, where organic waste gas causticizes to form non-toxic CO2 and H2O, thereby achieving the actual effect of cleaning the waste gas.

RTO in the whole process of work in the whole process of the acquisition of heat, the utilization rate of heat energy to achieve above 95%, complete the two-way goal of waste gas cleaning and energy conservation and environmental protection, is to solve the high concentration of volatile organic waste gas selection.

RTO regenerative heating principle: garbage incinerator for organic waste gas to carry out the preliminary treatment after operation, the mixed burning body, heating to a certain temperature (generally 730-780 ° C), make the organic chemicals in the exhaust produces REDOX reaction, form small molecules of water inorganic compounds (e.g., CO2, H2O), the centrifugal fan, smoke halogen platoon into the air. The high temperature vapor caused by air oxidation flows through the porcelain heat storage body, so that the porcelain body temperature began to “heat storage”, in order to solve the organic waste gas into the later, and save a lot of fuel.

Several regenerators are set up in the RTO system software to ensure that each regenerator has undergone heat storage, heat release reaction, cleaning and other procedures, and continues to work in a cycle. After the “exothermic reaction” of the regenerator, clean gas should be introduced to clean the room. After the cleaning, it can be entered into the “heat storage” process, otherwise the molecular structure of the residual waste gas is discharged into the air with the chimney, thus reducing the high efficiency.

The organic waste gas flowing through the regenerative porcelain body, after heating, the temperature rapidly increases, the temperature in the furnace can achieve 800°C, VOCs in the organic waste gas here at high temperature immediately converted into carbon dioxide and water vapor, producing non-toxic, odorless high temperature flue gas.

Mixture through the temperature slightly low heat storage porcelain, a lot of heat energy that is, from migration to the regenerator in flue gas, organic exhaust gas for heating the next circulation system, high temperature flue gas temperature greatly reduced, and then through direct expansion type heat exchanger system software and other materials, further reduce the flue gas temperature, eventually into the outdoor air.

Into the field: heating furnace exhaust gas, chemical plant electrophoresis principle, spraying, spraying, packaging printing, electronic devices and other fields of exhaust gas solution.

Suitable for all kinds of industrial waste gas treatment

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for China Precipitator Exporters – RTO regenerative waste gas incinerator – Jinming , The product will supply to all over the world, such as: Tanzania, Burundi, Cannes, We have more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products!

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.