China Drying Equipment – High temperature powder curing bridge drying furnace-jm-900 – Jinming

China Drying Equipment – High temperature powder curing bridge drying furnace-jm-900 – Jinming Detail:

Equipment composition description

1. Chamber Body

The chamber body is through type, the column and beam in the chamber body are welded with section steel to meet the load-bearing requirements of the chamber body and the workpiece. The inner plate of the chamber is made of 1.2mm high quality galvanized steel plate, the outer wall is made of 0.6mm galvanized corrugated steel plate, and the inner skeleton is made of U-shaped steel, Angle steel and galvanized steel plate. The thickness of the insulation layer of the chamber wall and bottom plate is 100mm, and the dissolved weight of the rock wool filled in the middle is 80Kg/m3. The integral insulation wall and roof are adopted, and the gaps between the boards are fully welded to form a fully sealed internal structure.

The whole heating unit is installed on the platform at the top of the chamber body, which adopts the steel frame and lays the pattern plate at the same time.

The chamber body is floor structure to prevent hot steam spillover, the entrance and exit of the drying room is equipped with electric sliding door, the door is closed during drying operation.

The greenhouse body is a modular structure, and an expansion joint is arranged in the middle of the whole length, which can compensate the thermal expansion displacement of the inner wall shell.

The chamber body of the drying furnace adopts convection heating, and the hot air enters the inner cavity through the tuyere and blows into the channel. The return air adopts adjustable air plate to balance the air volume and pressure.

A temperature sensor is arranged on the top of the chamber body to detect the temperature of each working area in the room.

2. Heating system

The gas hot blast stove consists of furnace body, combustion chamber, combustion machine, fan, filter device and other parts.

The gas heating indirect gas heating method, it is through the combustion machine in the stainless steel heat energy conversion device combustion, and then through the high temperature induced draft fan and circulation pipe, the hot air transported to the furnace heating, so that the cycle reciprocating heating air, so that the powder curing furnace to achieve the required hot air value.

Heat energy converter is made of high temperature resistant stainless steel plate (2 ~ 3mm), the cavity is the introduction of foreign advanced technology, through CAD design, with fast heating, long service life and other advantages. The inner plate of hot blast stove is galvanized steel plate with high temperature resistance and aging resistance. The outer plate is cold rolled steel plate with high quality. The inner and outer wall panels are filled with δ150mm rock wool for insulation.

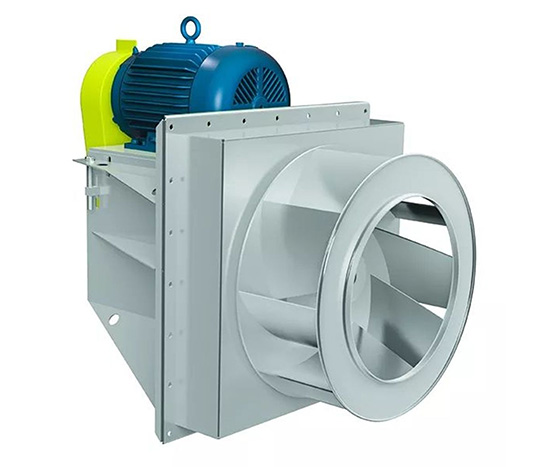

Hot air circulation fan adopts national high quality products, impeller adopts temperature resistant material, with high temperature resistance, low noise, balanced operation and other characteristics. The bearing of fan adopts air-cooled refueling cooling mode to ensure smooth convection circulation of hot air and heat balance in the dry passage.

GCF type high temperature fan is used for hot air circulation fan.

The powder furnace is continuously adjustable in the range of 180 ~ 220℃, and can adapt to fast shutdown. The time to close the circulating fan is not more than 30 minutes after the burner stops burning.

The high efficiency filter system adopts high temperature resistant high efficiency filter, which is installed between the fan suction outlet and the heat exchanger. It adopts “W” movable removable installation mode, with access door left on the side for easy cleaning and installation.

The fresh air outlet is located on the inlet side of the box body, and the tuyere is 350×350. It is equipped with high efficiency filter screen and air volume adjustment device. The whole fresh air can be adjusted to ensure the fresh air in the furnace. Advantages Excellent thermal insulation performance.

Used for all kinds of workpiece painting, other models can be customized.

Product detail pictures:

Related Product Guide:

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for China Drying Equipment – High temperature powder curing bridge drying furnace-jm-900 – Jinming , The product will supply to all over the world, such as: New York, Mongolia, European, Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!